Key Takeaways

- Platinum multi-head weighers are vital for precise and efficient food packaging processes.

- Learn best practices for installing and maintaining multihead weighers to maximize packaging system performance.

- Load cell sensors, vibratory feeders, and weigh buckets are crucial components to consider.

- Follow safety guidelines and ensure proper integration with your feeding system and computerized control system.

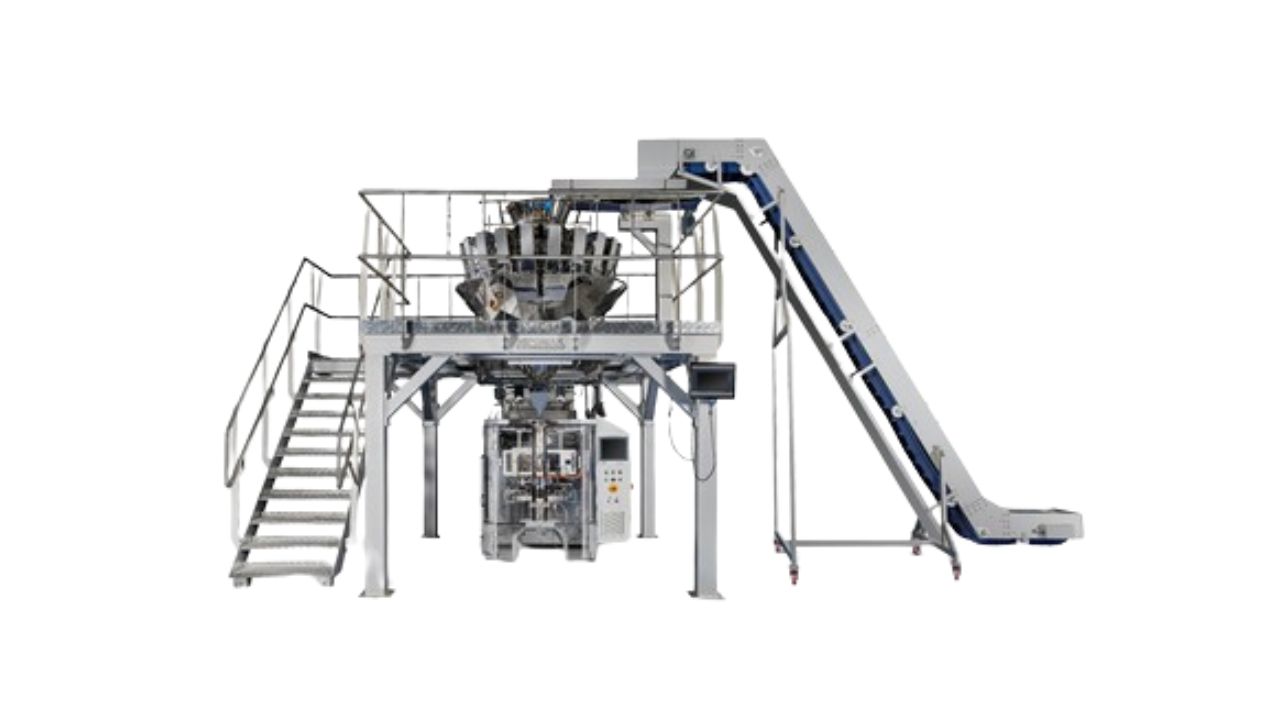

The Platinum multi-head weigher is a highly accurate, efficient, and versatile piece of equipment designed to meet the demands of high-volume food packaging and other industrial packaging systems. Often used in the food industry, this multihead scale is engineered for precision, speed, and reliability. Its use across industries for packaging granular products, irregularly shaped products, and more makes it indispensable.

This guide will walk you through the installation and best practices for setting up the Platinum multi-head weigher, ensuring that your production runs smoothly and effectively.

Components of the Platinum Multi-Head Weigher

Understanding the various components of the Platinum multi-head weigher is crucial for ensuring its optimal performance. Below are the key components:

- Multihead Weighers: These are essential for combination scales that combine multiple weigh buckets to fill bags or containers quickly and accurately.

- Load Cell Sensors: The load cell is responsible for weighing the product accurately, ensuring that the target weight is achieved.

- Weigh Buckets: These weigh buckets are where the product is collected before it is dispensed into the packaging.

- Vibratory Feeder: This helps in moving the product smoothly from the feed bucket to the weighing buckets.

- Infeed Funnel: The infeed funnel directs the product into the feeding equipment.

Proper integration and maintenance of these components are essential for maximizing the machine's potential in your production line.

Installation Process for the Platinum Multi-Head Weigher

Proper installation is the first step in ensuring your multihead weighers perform at their best. Below are the essential steps to follow for installing your Platinum multi-head weigher:

- Site Preparation

Before you begin, ensure that the area where the multihead weigher will be installed is level and clean. This will prevent any issues related to misalignment or contamination of products during the weighing process. Ensure that you have a stable surface for placing the machine.

- Mounting the Weighing Machine

Mount the multihead scale on a sturdy frame or base. Ensure it is securely fastened to prevent movement during operation. It is crucial that the machine stays perfectly aligned to maintain weighing accuracy.

- Load Cell Integration

Install the load cell sensors carefully to ensure that they can accurately measure the weight of the products in the weighing buckets. The load cells should be connected to the computerized control system to transmit weight data in real-time.

- Connecting the Feeding Equipment

Connect the vibratory feeder, belt feeders, and linear vibrators to the multi-head weigher. This ensures that the product moves smoothly and consistently from the feeding pans or feed bucket into the weighing buckets.

- Calibration

Calibrate the machine to ensure that the target weight is accurate. Run several tests using products of different weights and types, including granular filler and irregular shaped products, to confirm the system is functioning correctly.

- Signal Connecting

Ensure that all signal connections between the multi-head scale, computerized control system, and check weigher are properly established. This is critical for maintaining operational efficiency and for troubleshooting any issues during production.

Following the correct installation process for your Platinum multi-head weigher is key to ensuring that it performs at its peak. By preparing the site, mounting the machine securely, integrating the load cells, connecting the feeding equipment, and calibrating the system accurately, you set the stage for smooth and efficient operation.

Best Practices for Using the Platinum Multi-Head Weigher

Once the Platinum multi-head weigher is installed, it is important to follow best practices to ensure long-lasting performance and consistent results. Here are some tips to help you get the most out of your system:

1. Regular Calibration

Ensure that you calibrate the multihead scale regularly to maintain weighing accuracy. This is particularly important if you are packaging different product types. Regular calibration will help you stay within the target weight and maintain consistency.

2. Proper Maintenance of Components

Make sure to regularly inspect the weigh buckets, load cells, and vibratory feeders for wear and tear. Clean them to avoid product build-up, which could interfere with packaging processes. Also, ensure that all parts, such as the vibratory weigh and weight hoppers, are functioning properly.

3. Use of Non-Stick Coating

For food packaging, especially in the food industry, it's crucial to maintain hygiene. Apply a non-stick food-grade Teflon coating to the components, like the weighing buckets and feeding pans, to prevent contamination and ensure smooth operation, particularly with sticky products.

4. Implement a Safety Check Routine

Follow safety guidelines for the proper use of the multihead scale. These may include wearing appropriate protective gear, ensuring that the machine is safely turned off before maintenance, and keeping the area clean and dry.

5. Optimize Feeding System Efficiency

Ensure that the feeding system is running at optimal speeds. Slow feeding can cause delays in the packaging process, while overly fast feeding can lead to inaccurate weighing. Adjust the vibratory feeder and infeed funnel accordingly to maintain smooth product flow.

Optimize Your Packaging Process with the Platinum Multi-Head Weigher

The Platinum multi-head weigher is an essential piece of equipment for any high-volume food packaging operation. Proper installation, maintenance, and following best practices will ensure that the system performs optimally, reducing waste and improving production efficiency.

By adhering to the installation guide and best practices outlined above, you can maximize the performance of your multihead scale and streamline your packaging processes. If you're ready to enhance your food packaging operations, reach out to us today and learn how the Platinum multi-head weigher can transform your business.

Contact us today for a consultation on how the Platinum multi-head weigher can improve your packaging operations and increase efficiency. Let us help you integrate a custom solution that meets your specific needs.

Frequently Asked Questions

Q1. What is the purpose of the multihead scale in the packaging system?

The multihead scale is designed to accurately weigh and distribute products into containers or pouches. It ensures that the correct target weight is met, reducing waste and improving the efficiency of the packaging process.

How do I know if my Platinum multi-head weigher is correctly calibrated?

You can test calibration by using known weights and comparing the reading on the weighing machine to the actual weight. If the readings are consistent and accurate, then the system is calibrated correctly.

Can I use the multihead weigher for packaging irregular shaped products?

Yes, multihead weighers are versatile and can be configured to handle irregular shaped products. However, adjustments to the feeding system and weigh buckets may be needed for optimal performance.

What maintenance is required for the multihead scale?

Regular cleaning of the vibratory feeders, weighing buckets, and load cells is important. Additionally, check for any wear on the feed buckets and vibratory weigh components, and calibrate the system periodically.

Can I integrate the Platinum multi-head weigher with other equipment in my food packaging line?

Yes, the multihead scale is designed to integrate easily with other feeding equipment, such as belt feeders, check weighers, and discharge chutes. This allows you to create a seamless packaging system.