WE OFFER A SPECIAL RANGE OF COMPLIMENTARY SERVICES

Wolfpack has forged a reputation for ingenuity, precision, and consistency. Whether it is integrating with equipment you already have, custom building a solution just for you, or designing a complete line from A to Z.

Your success is our success. Our client-centric approach ensures that your unique needs are at the forefront of everything we do. Join forces with a packaging machinery provider that’s invested in your growth. Our solutions are engineered to scale alongside your business, enabling you to seize new opportunities.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s.

Our engineers and technicians boast an average of 20 years of hands-on experience within the packaging automation sector. This wealth of knowledge spans across various industries and encompasses proficiency with a wide array of machine types.

Our solutions include cutting-edge equipment that features top quality components to ensure optimal performance, durability, and user-friendliness to give you peace of mind for years to come.

Our excellent customer support, technical assistance, and after-sales services set us apart. Our dedicated team is committed to providing swift assistance, ensuring minimal downtime and maximum operational efficiency.

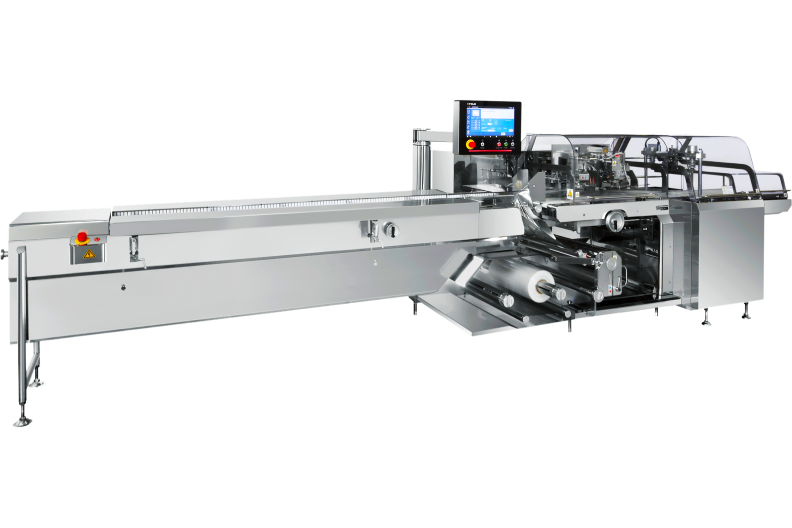

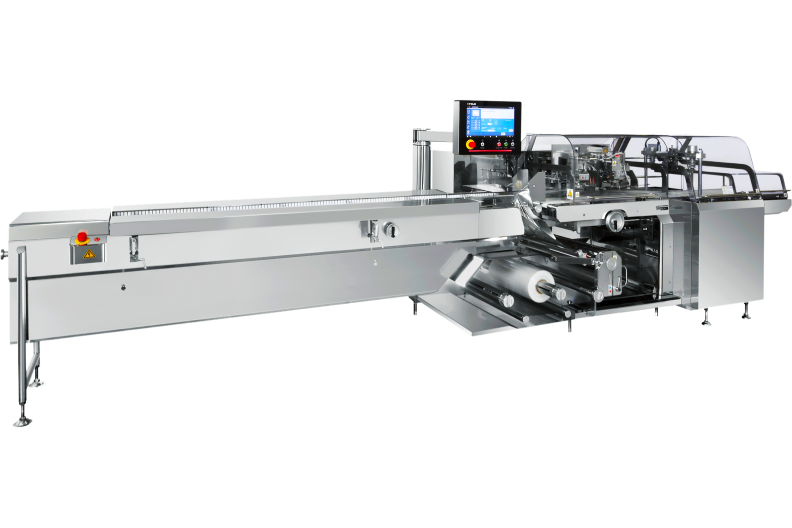

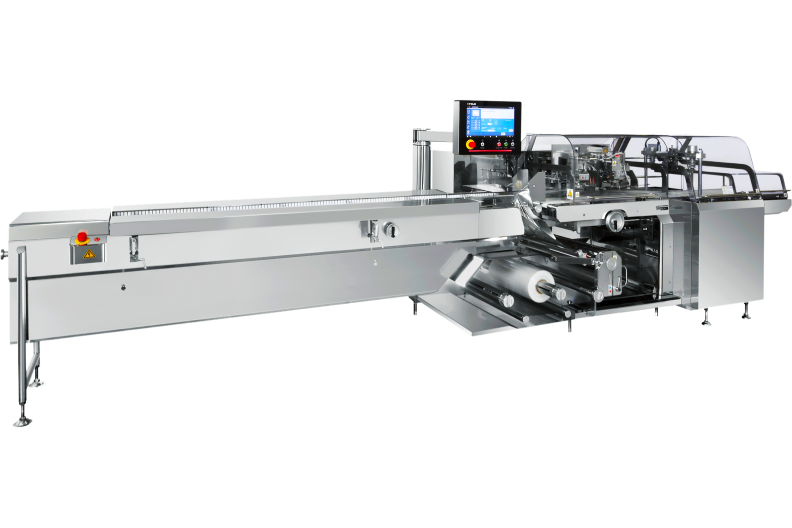

Introducing the Inverted Flow Wrapping Machine, a game-changer in the world of packaging automation. This state-of-the-art device is designed to streamline the packaging process for a wide range of products. With its unique inverted design, the machine effortlessly forms, fills, and seals packages with exceptional precision and efficiency. Ideal for wrapping loose or easy melting items.

Please try to be as detailed as possible so we can provide you with the most accurate information.

370 Goddard, Irvine, CA 92618

PHone – (949) 407-9281

Email – daniel@wolf-packing.com

370 Goddard, irvine ca 92618

Monday – Friday 9am – 5pm

Closed on Weekends

© Copyright Wolf-packing company

Please try to be as detailed as possible so we can provide you with the most accurate information.

370 Goddard, Irvine, CA 92618

PHone – (949) 407-9281

Email – daniel@wolf-packing.com

370 Goddard, irvine ca 92618

Monday – Friday 9am – 5pm

Closed on Weekends

© Copyright Wolf-packing company