Key Takeaways

- Tailoring your packaging to your product type, whether liquid, powder, dry goods, or snacks, ensures product safety and consumer appeal.

- Selecting the right packaging system is essential to meet the specific needs of your product, such as barrier properties and sealing methods.

- Industries such as food and beverage have strict packaging requirements that must prioritize food safety, shelf life, and consumer convenience.

- Wolf Packing offers custom packaging systems designed to enhance efficiency while protecting your product throughout its journey from production to delivery.

- Sustainable packaging options, such as compostable take-out containers and recyclable packaging, support your brand’s commitment to eco-friendly solutions and the circular economy.

When it comes to packaging, every product is unique, and so are its packaging needs. The type of product you sell—whether it's liquids, powders, dry goods, or snacks—plays a huge role in determining the best packaging system for your business.

Choosing the right packaging machine and system is essential for ensuring your product stays safe, fresh, and appealing to consumers.

In this guide, we’ll explore how to select the best packaging equipment for your product category, what factors to consider, and how Wolf Packing can provide you with tailored solutions.

Understanding Your Product’s Needs

Before you can select the best packaging system, it’s important to understand the specific needs of your product. Different categories of products require different types of packaging solutions. Let's break down some common product types and the packaging options best suited for them.

Liquids

Liquids are one of the trickiest products to package. They require packaging that prevents leaks and ensures freshness. For liquid products like juices, oils, or sauces, the packaging must also offer a barrier to preserve shelf life and protect from contamination. A Vertical Form, Fill, & Seal system is an ideal choice for liquid packaging. This system allows for precise filling, ensuring the right amount of liquid is sealed in each pouch, providing an effective solution for your liquid-based products. Packaging materials such as foil pouches or flexible packaging are perfect for liquids that need extra protection from external elements.

Powders

Powdered products such as spices, protein powders, or powdered drink mixes require packaging that minimizes exposure to air and moisture to maintain quality. Packaging systems that offer airtight seals, such as pre-made pouch bagging machines, are perfect for powder products. These machines create reliable seals that keep moisture and contaminants out, preserving the product's freshness and shelf life. Recyclable packaging options, such as gusset bags or flat heat seal bags, ensure that powder products are packaged efficiently and safely, aligning with eco-friendly packaging goals.

Dry Goods and Snacks

For dry products like grains, cereals, or snacks, packaging must provide durability and ensure easy storage. The packaging system must also be efficient for mass production, especially when dealing with high-volume products. Jar packaging systems work well for these items, especially when you need to offer a premium look and reusable packaging. These systems not only provide a secure seal but also allow for creative and functional packaging designs. For added convenience, stand-up zipper pouches are perfect for snacks, offering resealability and a consumer-friendly experience.

Key Considerations for Packaging Equipment Selection

When selecting the right packaging system for your product, it’s important to consider several factors. Let’s take a closer look at the most important ones:

Product Type

The most obvious factor to consider is the type of product. Whether you're packaging liquids, solids, powders, or snacks, the product’s properties—such as viscosity, texture, and shelf life—determine the packaging solution. Wolf Packing’s custom packaging systems are designed to meet the specific needs of each product type. For products requiring extra protection, such as glass bottles or aluminum cans, our packaging systems incorporate barrier properties that prevent damage during transit.

Industry

Different industries have different requirements when it comes to packaging. For example, the food and beverage industry often requires packaging that not only keeps the product safe but also promotes food safety and extends shelf life. Products in industries like healthcare, cosmetics, and pet care may have additional regulations to follow. Our team understands the unique demands of various industries and provides packaging equipment solutions that comply with these regulations, including options for food-safe packaging and BPA-free materials.

Shipping Needs

Another key factor in your packaging decision is how the product will be transported. For products that will be shipped long distances or stored for extended periods, packaging must protect against environmental factors such as moisture, light, and temperature fluctuations. A packaging equipment selection that incorporates barrier films or inspection systems ensures that your product will arrive in perfect condition. For items like take-out containers or cookie bags, using corrugated cardboard or clamshell containers helps protect the product during transportation and ensures consumer satisfaction upon arrival.

Tailored Packaging Solutions by Wolf Packing

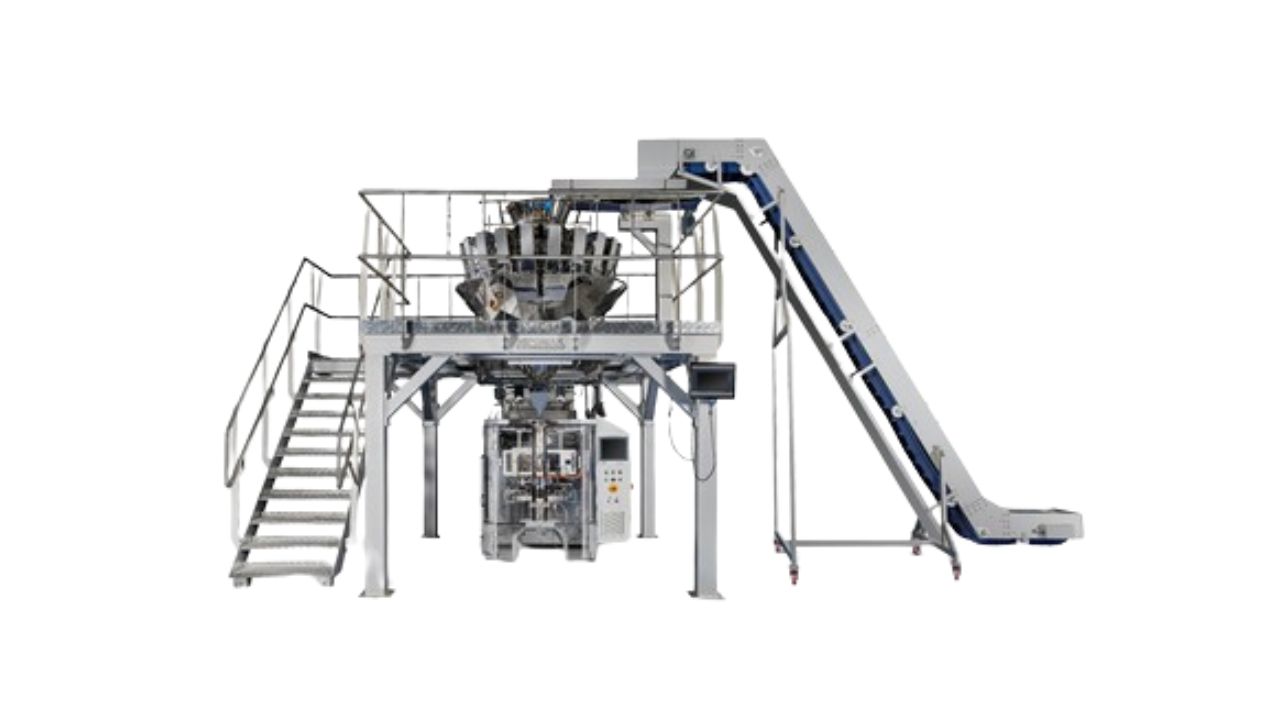

At Wolf Packing, we don’t just sell packaging equipment—we provide solutions. Our packaging systems are customized to fit the specific needs of your products. Whether you need a Vertical Form, Fill, & Seal system for liquid packaging or a Pre-made pouch bagging machine for powders, we’ve got you covered. Our tailored solutions extend to industries that require sustainable packaging options, including recyclable packaging and compostable take-out containers, supporting your commitment to the circular economy.

Our team will work closely with you to design a system that maximizes efficiency while ensuring your product remains safe and fresh. We understand that every product is unique, and we offer packaging solutions that help your business grow. From jar packaging systems to inspection systems, our wide range of packaging solutions ensures your products are packaged securely and efficiently.

Unlock the Power of Custom Packaging with Wolf Packing

Choosing the right packaging is critical for maintaining product quality and meeting consumer demands. Whether you're working with liquids, powders, dry goods, or snacks, Wolf Packing has the experience, expertise, and equipment to provide tailored solutions that fit your business's needs. We take the time to understand your product and your goals, offering packaging systems that are built to last and meet industry standards. With options like biodegradable sugarcane to-go boxes and flexible packaging, we help you deliver products that stand out while aligning with sustainability goals.

Ready to explore your packaging options? Let Wolf Packing help you package smarter. Our solutions grow with you! Contact us at (657) 776-1813 to learn more about our custom packaging systems and how we can support your business’s growth.