Key Takeaways

- Auger filler machines are essential for precise and efficient filling, especially for powder products and granular materials.

- There are different types of auger fillers, including automatic and semi-automatic, each suited to different production needs.

- Key features such as weight scales, fill heads, and filling accuracy ensure consistent, high-quality results across various products.

- Powder filling machines and auger powder filling machines are specifically designed for industries like pharmaceuticals, food packaging, and agriculture, ensuring precise product dispensing.

- Regular maintenance, proper calibration, and adjusting filling parameters based on product type are critical to maximizing the efficiency and lifespan of auger filler machines.

Auger filler machines are a staple in many industries, offering precise and efficient filling solutions, especially for powders, granules, and other dry materials.

They are essential in sectors such as the food and beverage industry, pharmaceutical industry, and agricultural industry, where filling accuracy is paramount. By utilizing an auger metering method, these machines dispense product with minimal waste and maximum efficiency.

Whether you're using a semi-automatic auger filler or a fully automatic auger filler, choosing the right weigh filler equipment is essential to optimize packaging processes and ensure the highest product quality.

Types of Auger Filler Machines

Before selecting an auger filler machine, it's important to understand the different types of machines available. Here are the main categories of filling machines used in various industries:

1. Automatic Auger Fillers

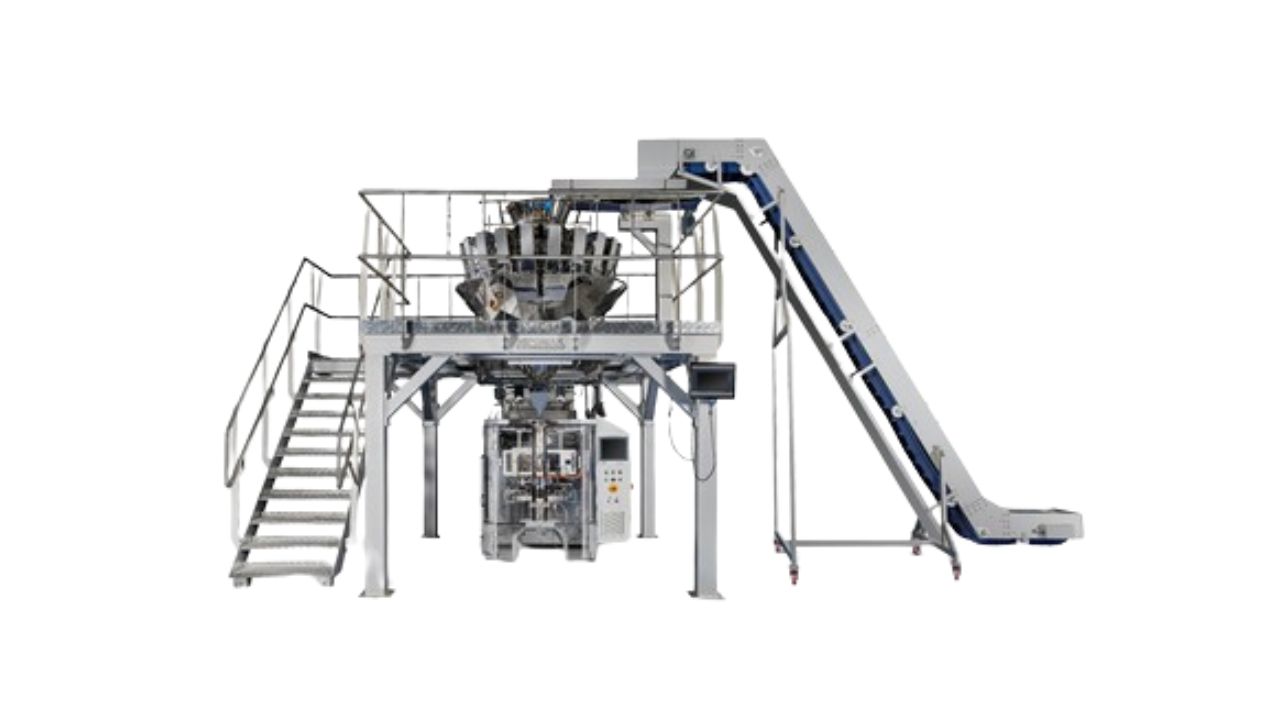

- Automatic auger fillers are designed for high-volume, high-precision filling. These machines are capable of continuous, automatic filling and are ideal for large-scale operations.

- Features include automatic filling, automatic powder auger feeding elevator, and integrated weight scales for precise target weight dispensing.

2. Semi-Automatic Auger Fillers

- Semi-automatic fillers offer a balance of control and automation. These machines require manual intervention for certain operations, such as loading products, but still provide high-speed filling and accurate results.

- Ideal for smaller production runs, these machines offer more flexibility and are easier to maintain.

3. Powder Filling Equipment

- This category includes auger powder filling machines specifically designed for dry powder filling machines. These machines are built to handle fine powders and granular products, ensuring a consistent fill and minimizing product waste.

- Powder filling equipment is commonly used in industries where precision is critical, such as in the pharmaceutical industry.

Understanding the different auger filler machines and their functionalities will help you make the right choice for your specific needs. Each type of filling machine is designed to address various filling challenges, ensuring accuracy and efficiency across production lines.

Key Features of Auger Filler Machines

When selecting an auger filler machine, it's important to understand the key features that will impact your operation’s efficiency:

Here are some of the most important features of auger fillers to consider:

- Filling Accuracy: Auger fillers offer exceptional filling accuracy by using an auger metering method that ensures precise measurements for each fill.

- Fill Heads: Multiple fill heads can be added to increase filling capacity and speed, making the machine ideal for high-volume production lines.

- Weight Scale: A built-in weight scale ensures that each package contains the correct amount of product, which is crucial for industries that require high compliance with product weight standards.

- Filling Parameters: Adjustable filling parameters, such as speed, target weight, and fill rate, allow you to customize the machine to your product's specifications.

These key features provide the flexibility and precision needed to handle various types of products, ensuring that each fill is accurate, efficient, and consistent.

Benefits of Using an Auger Filler Machine

Investing in an auger filler machine offers numerous benefits that will improve your overall packaging system:

Here are the top benefits of incorporating auger fillers into your operations:

- High-Precision Filling: Whether you're filling pouch bags, bottles, or cans, auger fillers ensure accurate measurements, reducing product loss and ensuring compliance with industry standards.

- Reduced Labor Costs: Fully automated filling machines reduce the need for manual labor, allowing employees to focus on other areas of production.

- Increased Production Speed: With automatic filling systems, auger fillers provide faster turnaround times, allowing for higher production capacity.

- Versatility: These machines can be used to fill a wide variety of products, including irregularly shaped products, granular products, and even thicker materials such as pastes.

Auger fillers offer a range of operational benefits, including increased efficiency, reduced labor costs, and versatility in handling various products. They are an excellent choice for improving your filling machinery.

Best Practices for Operating Auger Filler Machines

To ensure the smooth operation and longevity of your auger filler machine, follow these best practices:

1. Regular Maintenance

- Regularly clean and inspect auger filler components such as feed bucket, vibratory feeders, and auger powder filling machines to ensure smooth operation.

- For machines used in food packing, always use food-grade components to meet hygiene standards.

2. Calibrate for Accuracy

- Regular calibration of the auger filler is essential to maintain filling accuracy. This ensures that the target weight is always met, especially when switching between different product types.

3. Adjust for Product Type

- Adjust the filling parameters based on the type of product you're filling. For example, thicker materials might require slower speeds, while fine powders can be filled at higher speeds.

4. Monitor the Filling Process

- Keep an eye on the weight scale and filling machines during production to ensure that each product is filled to the right specifications.

By following these best practices, you can maintain optimal performance of your auger filler machines and ensure that your production runs efficiently with minimal downtime.

How to Choose the Right Auger Filler for Your Production Line

Selecting the right auger filler machine depends on a variety of factors, including your product type, production capacity, and industry-specific requirements. Here are some key factors to consider:

1. Product Type

- Powder products: Choose a dry powder filling machine or auger powder filling machine for granular or fine materials.

- Viscous materials: For thicker products, such as sauces or creams, a paste filling machine or piston filling machine may be more suitable.

2. Production Capacity

- If you have high-volume production needs, a fully automatic auger filler with multiple fill heads will provide the efficiency and speed you require.

- For smaller, less frequent production runs, a semi-automatic auger filler might be sufficient.

3. Industry Requirements

- For industries like food and beverage, pharmaceuticals, or chemicals, ensure the filling machinery meets specific compliance standards. Machines used in these sectors should also be able to handle various packaging formats, such as bottle-filling machines or pouch-filling machines.

Ready to Upgrade Your Filling System?

Choosing the right auger filler machine is critical for improving your production efficiency, maintaining filling accuracy, and optimizing packaging processes.

Whether you need a semi-automatic auger filler for smaller runs or a fully automatic auger filler for large-scale production, selecting the correct machine will significantly impact your operations. Ensure that you consider product type, production capacity, and industry requirements when making your decision.

Contact us today to learn how the right auger filler machine can optimize your packaging operations. Our expert team can guide you through the selection process and provide a customized solution tailored to your production needs.

Frequently Asked Questions

What types of products are best suited for auger filler machines?

Auger filler machines are ideal for powder filling, granular products, and other free-flowing materials. They are commonly used in the food packaging industry, pharmaceuticals, and the agricultural industry.

What’s the difference between a semi-automatic auger filler and a fully automatic auger filler?

Semi-automatic auger fillers require some manual operation, whereas fully automatic auger fillers operate autonomously, offering higher production rates and efficiency for large-scale operations.

How does an auger filler machine ensure accurate filling?

Auger fillers use an auger metering method that precisely controls the amount of product dispensed. The system works with weight scales and load cell sensors to ensure that the target weight is consistently met.

Can auger filler machines handle irregularly shaped products?

Yes, auger filler machines are versatile and can be adjusted to accommodate irregularly shaped products, although the setup might need fine-tuning depending on the product's flow characteristics.

What industries use auger filler machines?

Auger filler machines are commonly used in industries such as the food and beverage industry, pharmaceutical industry, chemical industry, and agricultural industry for automatic filling of powders, granules, and other materials.