Key Takeaways

- Industrial weighing and filling machines improve efficiency in food processing and packaging.

- These systems provide custom solutions to meet specific production line requirements.

- Weighing and feeding systems are crucial for material handling and automated lines.

- Weigh & fill systems ensure precise flow rates, package quality, and consistency.

- Learn how to integrate automatic weighing scales and flow wrap machinery into your production lines.

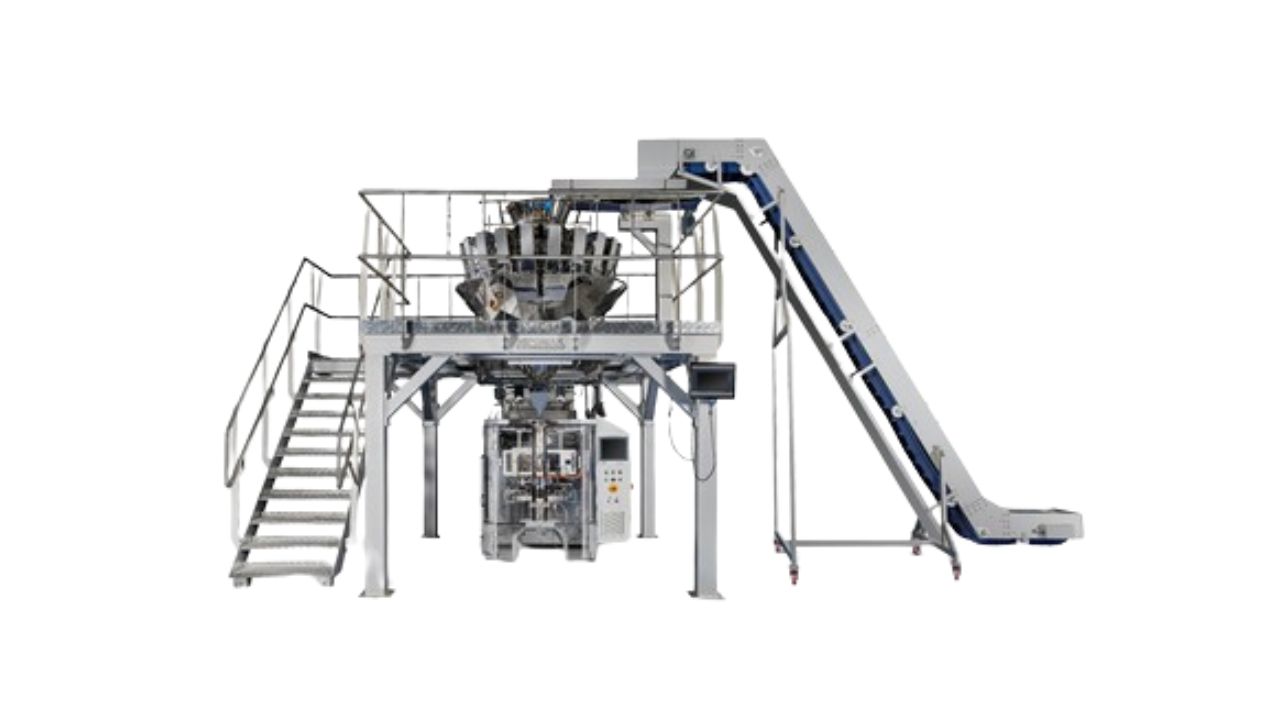

Industrial weighing and filling machines play a pivotal role in industries such as food packaging, pharmaceuticals, and chemicals. They ensure that every package is filled precisely, reducing waste and ensuring compliance with safety and regulatory standards.

In this guide, we will dive deep into the components, benefits, and applications of industrial weighing and filling machines, and explore how these solutions optimize the production lines in various industries.

Key Components of Industrial Weighing and Filling Machines

Weighing and filling equipment consists of several integral components designed to work together to deliver precision and speed. Here are some key components of these systems:

- Weighing Scales: The heart of the system, offering accurate measurement of the product's weight.

- Filling System: Efficiently dispenses products into packaging containers.

- Flow Rates: Ensures consistent and controlled product flow into containers.

- Automated Systems: Enable automated lines for seamless integration and reduced human error.

These components are built to enhance the functionality of packaging machinery, ensuring high-speed production without compromising product integrity.

Types of Industrial Weighing and Filling Machines

- Weigh & Fill Systems

- These systems are widely used in food processing and material handling industries. Weigh & fill systems offer a precise method of filling containers based on the exact weight of the material being dispensed. This allows manufacturers to maintain accuracy while maximizing production rates.

- Belt Feed Systems

- Belt feed systems are ideal for handling large volumes of materials in a production line. The continuous movement of materials ensures a consistent feed into the filling machines, helping streamline the filling process and maintain uniformity in each package.

- Automatic Weighing Scale

- The automatic weighing scale ensures that each product is weighed to the exact specifications required by the industry. This is particularly important in sectors like food packaging, where maintaining consistency is essential for both regulatory compliance and customer satisfaction.

- Flow Wrap Machinery

- Flow wrap machinery automates the packaging of products into pouches or flow wraps. It is ideal for food-grade equipment where maintaining product integrity and freshness is crucial. This system works in harmony with weigh filling systems to produce high volumes of sealed packages.

- Form-Fill-Seal Machines

- Form-fill-seal machines are designed to create bags from a roll of film, fill them with product, and seal them. These machines are highly versatile and can be used for various materials, including food products and chemicals.

Benefits of Industrial Weighing and Filling Machines

The adoption of industrial weighing and filling machines offers numerous advantages that are essential for modern production lines:

- Increased Efficiency: These systems enhance productivity by automating the filling process, reducing manual labor, and improving the flow rates of products.

- Improved Accuracy: Weighing and filling systems provide precise measurements, ensuring that each product is packaged correctly and that there is minimal waste.

- Customization: Many machines can be tailored to specific production line needs, offering custom solutions to suit the unique requirements of businesses.

- Scalability: As your business grows, these machines can be easily integrated into automated lines, helping your production scale seamlessly without the need for complete overhauls.

With these advantages, businesses can optimize their packaging processes and stay competitive in today’s fast-paced market.

How Weighing and Filling Machines Improve Production Line Performance

In a production environment, weighing and filling equipment can significantly improve overall production line performance. Here’s how:

- Integration with existing machinery: Weighing and feeding systems can be easily integrated into existing lines without major disruption.

- Increased Output: With high-speed machines, automated lines can operate around the clock, achieving higher output levels with reduced downtime.

- Quality Control: These systems ensure package quality by accurately filling containers and avoiding underfilling or overfilling.

- Energy Efficiency: Modern filling systems are designed to use less energy, reducing operating costs and minimizing the carbon footprint.

Industrial weighing and filling machines play a crucial role in enhancing the speed, accuracy, and efficiency of the packaging process in today’s highly competitive manufacturing environment. These machines streamline the filling system, allowing companies to achieve high production rates while maintaining exceptional package quality.

Transform Your Packaging Process with Industrial Weighing and Filling Machines

Industrial weighing and filling machines are essential for modernizing your production lines and ensuring consistent package quality. With the ability to integrate seamlessly into existing operations, these systems offer customizable solutions that help optimize production lines and reduce inefficiencies.

Whether you are in food processing, pharmaceuticals, or any other industry, investing in weigh & fill systems will help streamline your packaging process and set your business up for long-term success.

Contact us today to learn more about how Wolf-Packing Machine Company can help you achieve packaging excellence with our industrial packaging machines. Request a consultation, and let us tailor a custom solution for your business needs.

Frequently Asked Questions

What is the role of weighing and filling systems in food packaging?

Weighing and filling systems in food packaging ensure that each package is accurately filled with the right amount of product, enhancing consistency and minimizing waste. These systems are especially important for industries that require precise measurements for compliance with safety standards.

How do automated lines improve production efficiency?

Automated lines streamline the production line by reducing manual labor, improving accuracy, and increasing the overall speed of operations. These systems allow for continuous, uninterrupted production, leading to higher efficiency and reduced downtime.

Can industrial weighing and filling machines handle different materials?

Yes, weighing and feeding systems are highly versatile and can be customized to handle a wide range of materials, including powders, liquids, and solids. This makes them ideal for industries such as food processing, pharmaceuticals, and chemicals.

What types of industries benefit from these systems?

Industries such as food packaging, pharmaceuticals, chemical processing, and consumer goods manufacturing benefit from the use of weighing and filling equipment, as these systems enhance accuracy and speed in packaging processes.

Are these systems energy-efficient?

Yes, many modern filling systems are designed to be energy-efficient, helping businesses reduce energy consumption and lower operational costs while maintaining high performance.