Key Takeaways

- Multi-lane weighing belts are vital for high-accuracy material handling in production lines.

- Conveyor belt installation requires careful preparation of facility layout, power supply, and control systems.

- Proper installation of multi-lane checkweighers, load cells, and weigh sensors ensures accurate automatic weighing.

- Ensure that safety features, such as emergency stop buttons and fire-fighting systems, are included in your installation process.

- Understanding belt tension, belt tracking, and weighing capacity is essential for efficient operation.

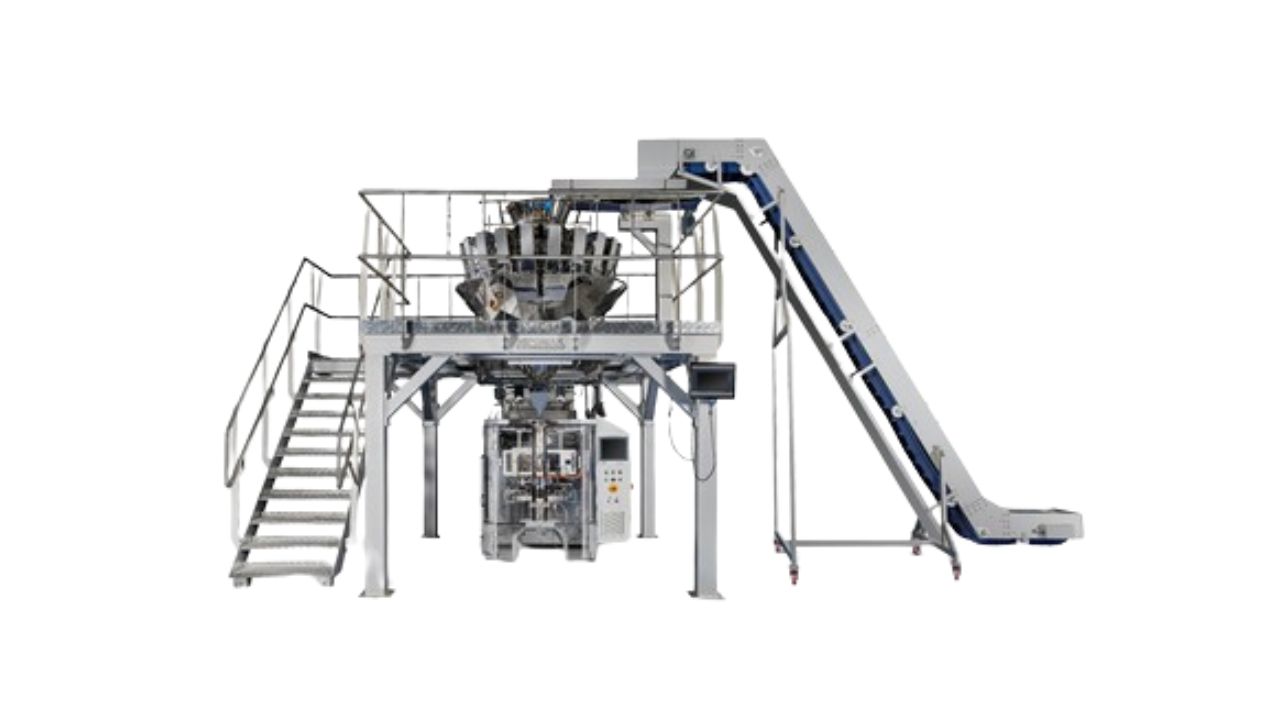

The multi-lane weighing belt is a key component in modern production lines, offering high-accuracy and high-speed material handling solutions. It is commonly used in industries such as the food industry, where automatic weighing is crucial for ensuring product quality and efficiency.

However, installing a multi-lane weighing belt is not a simple task—it involves proper facility layout preparation, ensuring that the system is well-integrated with the rest of the production lines. This guide will walk you through the key installation requirements, facility preparations, and best practices for successfully installing your belt conveyor system.

Key Installation Requirements for Multi-Lane Weighing Belt

Before you begin the installation process for your multi-lane weighing belt, certain requirements must be met to ensure proper operation and integration with your existing equipment.

Here’s a breakdown of the essential steps and considerations for installation:

1. Facility Layout and Space Considerations

- Adequate space is necessary for the multi-lane checkweigher and conveyor belt system to function properly. A careful facility layout is essential to avoid bottlenecks and ensure smooth operations across production lines.

- Consider the conveyor belt width and the required weighing capacity when determining the installation space.

- Ensure there is sufficient space for multilane singulators and converging conveyors, which are key components of the multi-lane weighing belt.

2. Power Supply and Control Systems

- A stable power supply is crucial for the continuous operation of the multi-lane weighing belt. Ensure that your facility has adequate electrical infrastructure to support the system.

- Control systems must be set up to monitor and manage the entire weighing and conveying process, ensuring accurate production data and seamless integration with other parts of the production line.

- Integration with metal detection systems is also crucial, especially in the food industry, to ensure that contaminants are detected and removed during production.

3. Weigh Sensors and Load Cells

- Weigh sensors and load cells are the heart of any weighing system. Accurate readings from these components are vital for maintaining the precision of the automatic weighing system.

- During installation, ensure that the load cells are calibrated and properly installed to ensure optimal weighing accuracy.

- Check for proper alignment and connection of weighing sensors to the control system to guarantee the correct flow of production data.

4. Conveyor Installation and Belt Tensioning

- Conveyor installation involves setting up the belt conveyor correctly, making sure it is level and securely fixed to the frame. Proper belt tracking and tensioning are critical for preventing slippage and ensuring that the belt runs smoothly.

- Install tensioning devices to adjust the belt's tension as required, ensuring consistent speed and accuracy in weighing tasks.

- Ensure that the gravity-assisted fixed scale is aligned with the conveyor belt to maintain consistent flow rates.

Safety Features and Measures

The installation process should also prioritize safety to protect workers and equipment. Below are some essential safety features and precautions that must be incorporated into your multi-lane weighing belt system:

- Emergency Stop Buttons: These are essential for immediately halting the conveyor belt system in case of an emergency. Install them at strategic locations for easy access.

- Fire-Fighting Systems: Especially important for systems running in high-risk areas, such as food packaging or chemical production, fire-fighting systems should be installed near the equipment.

- Safety Guards and Covers: Install safety guards around the belt conveyor to prevent accidents and ensure safe operation.

- Regular Equipment Inspections: Incorporate a schedule for equipment inspection to monitor the system’s condition and prevent any potential failures.

Maintenance Considerations for Multi-Lane Weighing Belts

After the conveyor belt installation is complete, ongoing maintenance services are necessary to ensure the longevity and proper functioning of the system. Here are a few key maintenance considerations:

1. Preventive Maintenance

- Schedule regular preventive maintenance to check the system’s components, including the vibrating groove feeder, load cells, and belt conveyor. This will ensure that the machine runs efficiently and can handle the multilane tasks.

2. Lubrication and Cleaning

- Proper lubrication of moving parts and regular cleaning of the conveyor system and weighing machinery are essential for maintaining smooth operations and extending the lifespan of the equipment.

3. Spare Parts Inventory

- Keep an inventory of parts, including vibratory plates, conveyor belt spares, and other components that are prone to wear and tear. This will minimize downtime and allow for quick replacements if necessary.

Streamlining Your Production Line with Proper Multi-Lane Weighing Belt Installation

Installing a multi-lane weighing belt is a crucial step in optimizing your production lines. From facility layout preparation to ensuring safety features and preventive maintenance, every aspect of the installation process contributes to the overall efficiency and productivity of your operation. By focusing on proper belt tensioning, ensuring accurate weighing sensors, and integrating safety measures, your conveyor installation will support long-term business productivity.

Contact us today for expert guidance on installing your multi-lane weighing belt system. Our team can assist you with facility preparation, installation, and maintenance solutions to keep your production line running smoothly and efficiently.

Frequently Asked Questions

What is the importance of facility layout for multi-lane weighing belt installation?

The facility layout ensures that there is enough space for the conveyor system and multi-lane checkweigher to operate smoothly. A well-planned layout avoids bottlenecks and optimizes the efficiency of the production line.

How do I ensure proper belt tension during installation?

Belt tension should be adjusted using tensioning devices to ensure proper tracking and smooth operation. Regular checks are necessary to prevent slippage and ensure consistent performance.

What safety features are essential in multi-lane weighing belt installation?

Key safety features include emergency stop buttons, fire-fighting systems, safety guards, and regular equipment inspection to protect both the operators and the equipment.

What is the role of load cells in the multi-lane weighing belt system?

Load cells provide accurate weight measurements by sensing the amount of product passing through the system. Proper calibration and installation of load cells ensure weighing accuracy across the production line.

What is the best way to handle material handling during multi-lane weighing belt installation?

Proper alignment and gravity-assisted fixed scale setup are essential to ensure smooth material handling and precise weighing capacity. Ensuring that the vibrating groove feeder and other related components are correctly calibrated helps in maintaining accurate flow rates.