Key Takeaways

- Food packaging systems play a vital role in extending shelf life, reducing spoilage, and preserving taste, especially in products like bakery goods and snacks.

- Wolf Packing’s vertical form, fill, and seal systems provide precise sealing for maximum freshness and product integrity.

- Consistency in sealing is crucial to maintaining quality and avoiding spoilage, with advanced sealing technologies offering precise control.

- Sustainability in food packaging is growing, and Wolf Packing supports eco-friendly materials while ensuring high production efficiency.

- Wolf Packing offers reliable technical support, ensuring smooth operations and compliance with safety standards in all packaging systems.

In the food industry, packaging plays a critical role in ensuring products remain fresh, safe, and appealing to consumers. Whether you’re packaging bakery goods, snacks, or liquid products, having the right food packaging machine and systems can make a huge difference. At Wolf Packing, we understand the intricacies of food packaging and offer advanced solutions designed to meet these challenges while enhancing efficiency. This article delves into how our equipment supports the critical goals of protecting shelf life, reducing spoilage, preserving taste, and improving product visibility on store shelves.

Enhancing Shelf Life and Preserving Product Integrity

Food packaging systems must prioritize more than just the visual appeal of the packaging. They are responsible for extending the shelf life of perishable goods, protecting them from external factors like air, moisture, and contaminants. Wolf Packing’s food-grade packing machines are designed to deliver a consistent, reliable seal, ensuring that your products stay fresh for as long as possible. This is especially vital in industries like bakery, coffee, and snacks, where freshness is paramount.

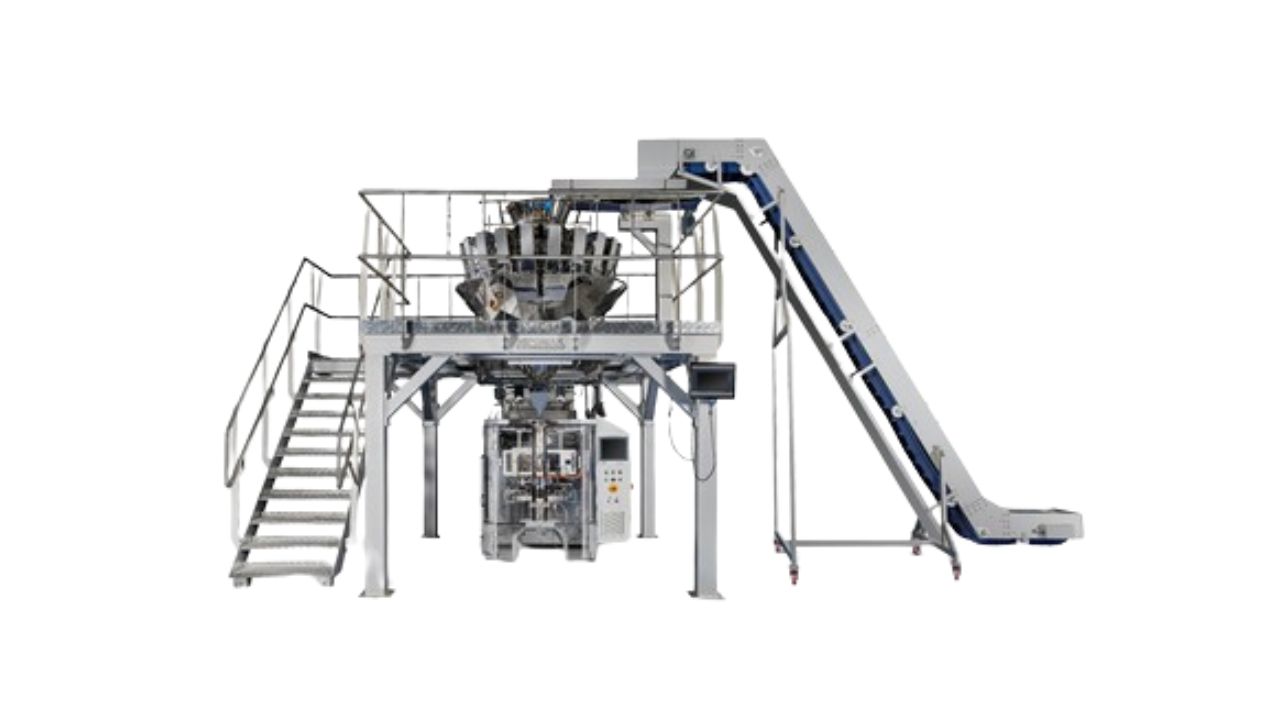

Our vertical form, fill, and seal systems are particularly effective in this regard. These machines efficiently package products in stand-up pouches, ensuring a secure seal that prevents spoilage while maintaining the taste and texture of the product. Whether it's a snack food packaging system for chips or a coffee packaging machine for ground coffee, these systems help create a packaging solution that supports the long-term quality of food products. Additionally, stand-up pouches offer excellent shelf visibility, which helps attract consumer attention and boost sales.

Precision and Consistency in Sealing

One of the most critical aspects of food packaging is ensuring the integrity of each seal. A faulty seal can compromise product freshness, safety, and consumer trust. Wolf’s advanced sealing technologies, including induction sealing and PLC controls, provide precise control over the packaging process, minimizing the risk of errors. This precision is crucial when packaging sensitive food products, such as cookies or potato chips, where the seal must prevent air from entering the package and causing spoilage.

By incorporating weighers and fillers into our food packaging systems, we ensure that the right amount of product is measured and sealed efficiently. Whether it’s for bulk packaging or individually wrapped products, these systems deliver accuracy and reduce waste, all while improving production efficiency. For high-speed packaging operations, our systems are designed to handle large volumes without sacrificing precision, making them ideal for businesses looking to scale up their production.

Tackling Challenges in Food Packaging

Food packaging faces unique challenges, especially in industries like wholesale bakery packaging, candy, and coffee. Packaging systems must account for the delicate nature of baked goods, the need for clear labeling, and the specific packaging requirements for products like coffee and snacks. For instance, when packaging bakery items, such as cookies, the system must prevent crushing while ensuring freshness. Similarly, coffee packaging requires a reliable seal to maintain flavor and aroma, while also making it easy for consumers to store the product.

Wolf Packing’s food packaging machines address these challenges with customizable features. Our pouch packaging solutions, for instance, come with a user-friendly color touchscreen interface, allowing operators to easily adjust settings for different products. This flexibility is particularly important for businesses that offer a range of products and need a system that can adapt to varying packaging requirements. Additionally, our machines comply with stringent safety standards, ensuring that your packaging operations meet industry regulations without compromising product quality.

Compliance with Safety Standards and Sustainability

Safety standards are paramount when it comes to food packaging. Whether it's meeting local regulatory requirements or ensuring the safety of the end consumer, our food packaging systems are built with these considerations in mind. We offer packaging solutions that not only meet current safety standards but also support sustainable packaging solutions for businesses looking to reduce their environmental footprint.

Wolf Packing also recognizes the growing demand for sustainable packaging solutions. Many of our machines are compatible with biodegradable films and recyclable materials, enabling companies to offer eco-friendly options without compromising the efficiency or safety of their packaging. These sustainable packaging solutions are becoming increasingly popular as consumers and brands alike focus on reducing waste and promoting environmental responsibility.

In addition to sustainability, Wolf Packing’s equipment helps minimize material waste during production. Our food packaging systems are engineered to optimize material usage, reducing scrap and improving overall production efficiency. This makes them an excellent choice for businesses looking to operate both sustainably and cost-effectively.

Innovation and Support: Helping Your Business Thrive

The food packaging industry is constantly evolving, with new technologies and regulations emerging all the time. At Wolf Packing, we are committed to staying at the forefront of these changes. Our food packaging systems are designed with the latest advancements in sealing technologies, automation, and efficiency, ensuring that your business remains competitive in a rapidly changing market.

We also offer comprehensive technical support to help you get the most out of your packaging machines. From initial installation to ongoing maintenance, our team is available to assist with any challenges that may arise. We understand that smooth, uninterrupted operations are key to your business's success, and our support team is always ready to provide timely assistance.

Packaging Smarter for a Better Future

At Wolf Packing, we offer food packaging systems that meet the demands of the food industry today while preparing you for tomorrow. Our solutions help improve production efficiency, extend shelf life, and ensure product integrity—whether you're in bakery packaging, snack food packaging, or liquid products. From advanced sealing technologies to precision weighers and fillers, our packaging systems deliver the quality and reliability your business needs to succeed.

Discover how Wolf Packing can help you enhance efficiency, improve safety, and reduce waste in your food packaging process. Contact us today at (657) 776-1813 and explore how our advanced food packaging solutions can support your business’s growth.