Key Takeaways

- Preventive maintenance is key to extending the equipment life of packaging machines and reducing unexpected repair costs.

- Regular machine maintenance helps maintain product quality, reduce downtime, and improve overall equipment effectiveness.

- Implementing a predictive maintenance program ensures that machinery such as volumetric fillers, vertical form fill seal machines, and stretch wrappers perform at peak capacity.

- Businesses in the food and beverage industry benefit greatly from effective packaging automation and maintenance schedules that align with production goals.

- Partnering with automation experts and customer support teams ensures that packaging solutions remain efficient and cost-effective.

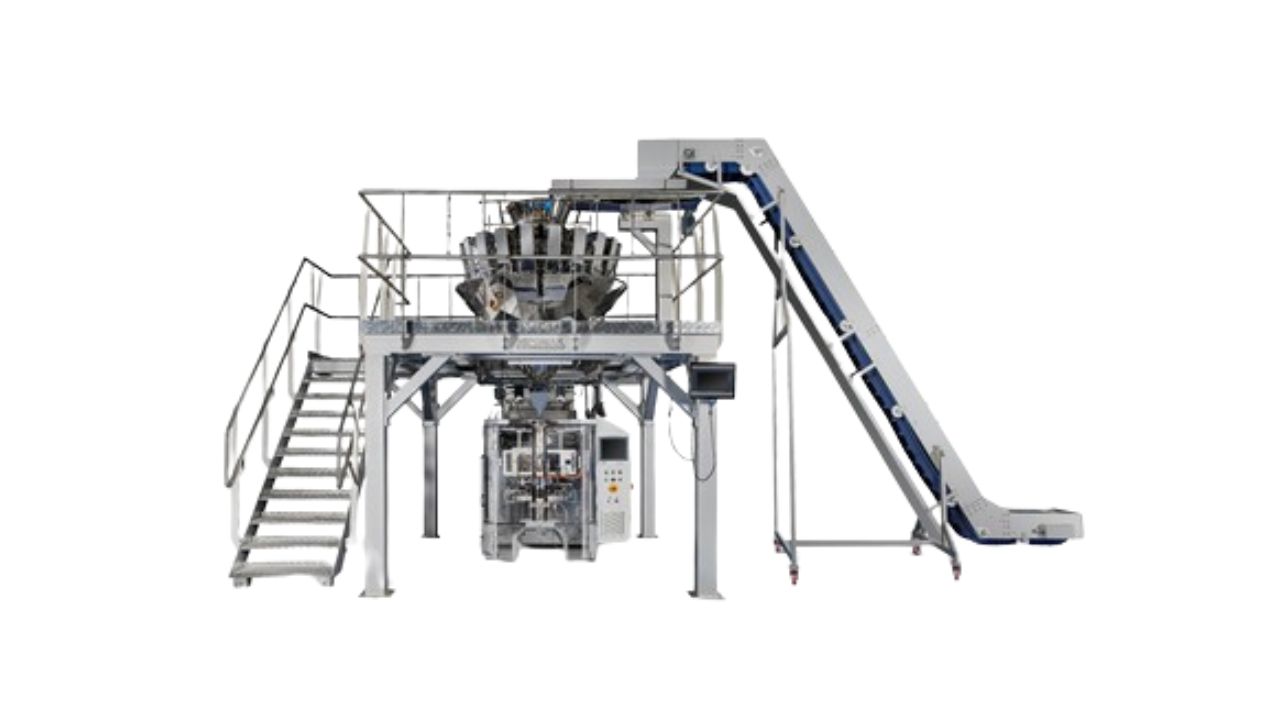

Packaging equipment plays a crucial role in ensuring the success of production lines, especially in industries like food and beverage, where product quality and efficiency are paramount. From vertical form fill seal machines to labeling systems, and even Paxiom automation machines and Pro Pac automation machines, regular machine maintenance is essential to avoid costly breakdowns and disruptions.

Preventive maintenance is not just about fixing problems when they arise; it is about anticipating potential issues before they impact production. With the right predictive maintenance program, manufacturers can extend the equipment life, optimize packaging automation, and significantly reduce operating costs.

In this guide, we’ll explore how preventive maintenance can lead to cost savings for your packaging equipment, providing long-term benefits to your business.

5 Benefits of Preventive Maintenance for Packaging Machines

Preventive maintenance for packaging machines offers several advantages that go beyond simply keeping the machines running smoothly. Below are five of the key benefits of investing in regular machine maintenance:

1. Extended Equipment Life

- Regular maintenance prevents wear and tear on critical components, such as volumetric fillers, stretch wrappers, and pouching systems. This prolongs the equipment life, allowing your packaging machinery to operate for a longer period without the need for costly replacements.

2. Reduced Downtime

- Unscheduled downtime is one of the largest costs associated with packaging equipment. By implementing predictive maintenance and regular checks, businesses can avoid unexpected breakdowns, leading to fewer interruptions in production. This is especially critical for high-volume machinery like robotic palletizing and end-of-line automation systems.

3. Improved Product Quality

- Packaging machinery like form-fill-seal equipment and conveyor systems must operate at precise settings to ensure product quality. Consistent maintenance time ensures that these systems are calibrated and functioning at their best, reducing the risk of defects in food packaging or flexible packaging.

4. Cost Savings

- While there is an upfront cost associated with preventive maintenance, it significantly reduces the likelihood of expensive repairs or emergency service calls. Regular maintenance ensures that parts are replaced before they fail, which reduces the cost of major repairs or unplanned shutdowns.

5. Increased Overall Equipment Effectiveness (OEE)

- OEE is a key metric that measures the efficiency of your packaging equipment. Regular maintenance improves your machines' sealing pressures, cycling speeds, and volumetric control, increasing production goals and improving the overall performance of your packaging systems.

5 Things to Include in a Preventive Maintenance Program for Packaging Equipment

A well-designed predictive maintenance program ensures that packaging machinery operates smoothly and efficiently. Below are some essential components that should be included in your machine maintenance program:

1. Scheduled Inspections

- Regularly scheduled inspections are essential for identifying any potential problems before they cause major issues. These inspections should include checks on components like sealing systems, labeling & coding equipment, and volumetric fillers. Ensure that pneumatic VFFS machines and servo-driven VFFS machines are calibrated for optimal performance.

2. Spare Parts and Inventory Management

- Spare parts like conveyor belts, robotic palletizing components, and flow wrapping parts should be readily available to reduce downtime. An inventory of parts should be managed effectively to ensure quick replacements during scheduled maintenance.

3. Lubrication and Calibration

- Ensure that all moving parts, such as those in conveyor systems, stretch wrappers, and slicing systems, are properly lubricated. Regular calibration of weighing & counting equipment and vertical form fill seal machines ensures that the equipment continues to meet product quality standards.

4. Belt Tracking and Tensioning

- For conveyor belt installation and stretch wrappers, proper belt tracking and tensioning devices are necessary to prevent wear and damage. Regular adjustments should be part of the maintenance schedule to ensure the belts run smoothly.

5. System and Component Testing

- Regular testing of control systems, load cells, form fill seal machines, and labeling systems ensures the equipment performs as expected. Use diagnostics tools to monitor the functionality of these systems and identify potential failures before they affect production.

Cost Breakdown of Preventive Maintenance for Packaging Equipment

Understanding the cost components of preventive maintenance is crucial for businesses to budget effectively and plan for long-term savings. Here’s a breakdown of the typical costs associated with a maintenance program for your packaging machinery:

- Scheduled Maintenance Fees: These are recurring costs for inspections, lubrication, and adjustments. Depending on the complexity of your packaging solution, these fees can range from a few hundred to a few thousand dollars per visit.

- Parts and Labor Costs: While preventive maintenance can reduce emergency repairs, there may still be costs for spare parts and labor. It’s essential to include wearing parts such as forming tubes, sealing elements, and vacuum seals in your budget.

- Emergency Repair Fees: Although preventive maintenance reduces the likelihood of sudden breakdowns, some businesses may still experience unexpected issues. It’s advisable to budget for emergency repairs outside of the regular maintenance program.

- Technology Upgrades: As packaging machines evolve, there may be costs associated with software updates or hardware maintenance to ensure your systems are up to date.

Understanding the cost breakdown of preventive maintenance for your packaging equipment allows you to budget effectively and plan for long-term savings.

4 Best Practices for Preventive Maintenance of Packaging Equipment

To ensure that your packaging machinery continues to perform efficiently, implement these four best practices for preventive maintenance:

1. Create a Comprehensive Maintenance Schedule: Develop a maintenance calendar that includes routine checks for each piece of equipment. Ensure that inspections are conducted at regular intervals to prevent unplanned downtime.

2. Train Machine Operators: Machine operators play a crucial role in ensuring the smooth operation of your packaging machines. Provide regular training to ensure operators can identify early signs of equipment failure and take appropriate action.

3. Monitor Key Performance Metrics: Use production data and machine monitoring systems to track metrics like sealing pressures, bag assembly, and cycling speeds. This data will help you identify any potential inefficiencies in the packaging process and ensure your machines are running at peak performance.

4. Partner with Automation Experts: Automation experts can help you design a predictive maintenance program tailored to your business. By working with specialists, you can optimize your packaging automation for maximum efficiency and cost savings.

Implementing these best practices for preventive maintenance will ensure your packaging equipment operates efficiently and reliably.

Enhance Efficiency and Reduce Costs with Preventive Maintenance for Packaging Equipment

Preventive maintenance is a powerful tool for ensuring the longevity and efficiency of your packaging machinery. By implementing a predictive maintenance program, businesses can reduce costs, avoid unexpected downtime, and improve product quality over time.

With a solid maintenance schedule, regular equipment inspections, and proper spare parts management, your packaging machines can continue to deliver outstanding performance, ultimately contributing to long-term savings and business productivity.

Contact us today to learn more about how preventive maintenance can enhance your packaging machinery performance. Our team is here to help you create a cost-effective maintenance plan tailored to your needs.

Frequently Asked Questions

What is included in preventive maintenance for packaging machines?

Preventive maintenance includes scheduled inspections, lubrication, calibration, spare parts replacement, and system testing to ensure the equipment operates smoothly and efficiently.

How often should I schedule maintenance services for my packaging equipment?

The frequency of maintenance depends on the type and usage of the equipment. For high-volume food packaging machines, monthly or quarterly maintenance is recommended, while lighter use may require semi-annual checks.

What are the benefits of preventive maintenance for packaging machines?

The main benefits include extended equipment life, reduced downtime, improved product quality, and lower overall maintenance costs. Preventive maintenance ensures that your packaging machinery operates efficiently.

How can I improve the performance of my packaging machinery?

Regular maintenance of components like conveyor systems, volumetric fillers, and sealing technology is essential for maintaining high performance. You should also use predictive maintenance to identify potential issues before they affect production.

Can predictive maintenance reduce costs for my packaging machinery?

Yes, predictive maintenance helps you address issues before they lead to expensive breakdowns. By monitoring equipment health and using real-time data, you can schedule maintenance more effectively and avoid unplanned repairs.