Key Takeaways

- AI in packaging machines and predictive analytics improve efficiency, reduce waste, and support real-time decision-making.

- Inspection systems, machine vision, and smart weighers ensure product accuracy and consistent quality at high speeds.

- IoT-enabled maintenance and cloud-connected systems offer real-time visibility and inventory control across the supply chain.

- Sustainable packaging focuses on reducing material usage, enabling recyclable options, and lowering carbon emissions without sacrificing performance.

- Smart packaging technologies like QR codes and Augmented Reality deepen consumer engagement and streamline product development.

The packaging industry is undergoing a revolution powered by smart automation. Today’s packaging lines aren’t just fast—they’re intelligent, adaptive, and capable of driving real value across the supply chain.

At Wolf Packing, we’re leading this evolution with automated packaging systems that blend human experience with cutting-edge technology. From AI-powered software to predictive maintenance, we're innovating where it matters most—dry food, snacks, and powder packaging.

Smarter Machines, Smarter Results

Packaging automation is no longer a luxury—it’s a necessity. AI in packaging machines enables real-time decision-making, reducing packaging waste and improving quality control.

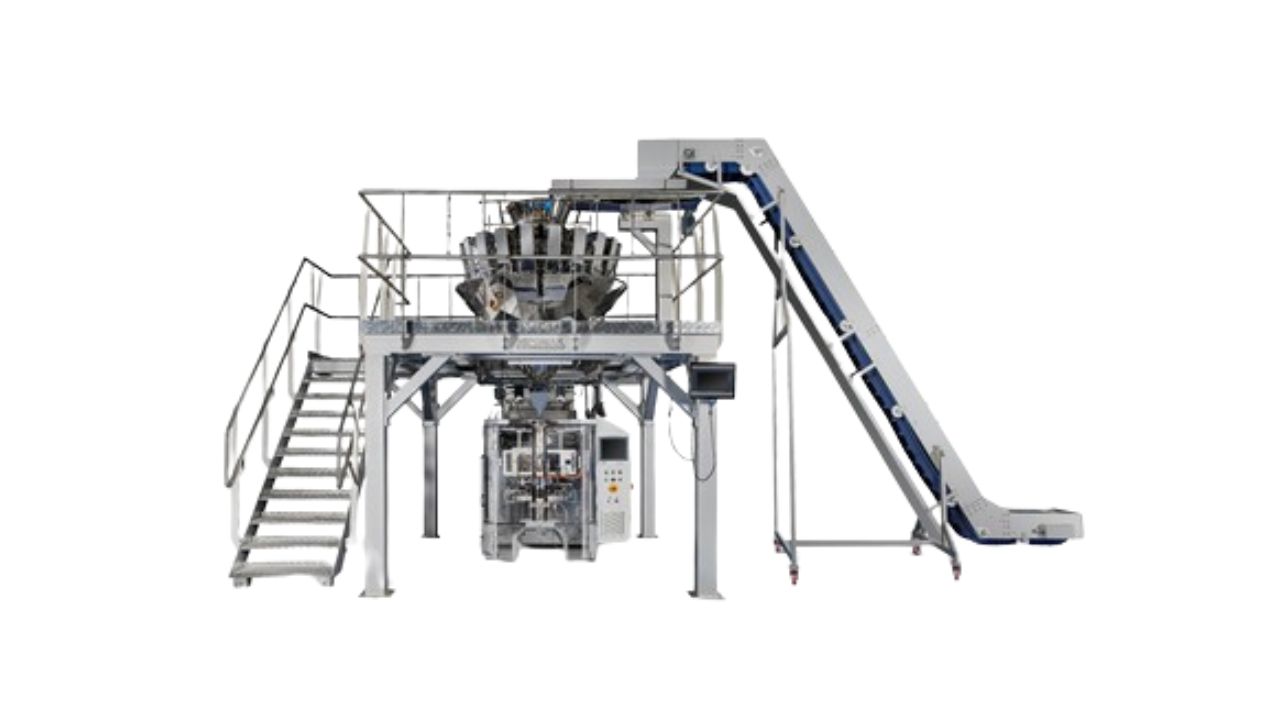

Through machine learning algorithms and digital twins, packaging systems can now forecast material usage and machine downtime. Our Vertical Form Fill Seal Systems are engineered to maximize uptime and minimize resource loss.

The Power Of Precision: Weighers And Inspection Systems

Precision is key in any packaging line, especially when handling diverse packaging types. Our weighers are integrated with advanced inspection systems to ensure accuracy and product integrity.

Machine vision and computer vision tools help detect inconsistencies before they become costly mistakes. These smart packaging lines deliver quality assurance without compromising on packaging speed.

Cloud-Connected And IoT-Enabled Systems

Packaging automation isn’t confined to the production floor. With IoT-enabled maintenance and cloud monitoring, we ensure machines stay connected, efficient, and proactive.

RFID tags and QR codes support traceability and inventory management across fulfillment centers. This kind of automation gives operators real-time visibility into their operations, improving overall system reliability.

Horizontal Flow Wrapping System: Redefining Consistency

In snack packaging, consistency is non-negotiable. Our Horizontal Flow Wrapping Systems deliver clean, consistent seals while maintaining flexibility across multiple packaging materials.

By using deep machine learning and generative AI, these systems can adjust settings automatically based on the product and film. That’s how we reduce waste and carbon emissions—without slowing production.

Veteran-Engineered Solutions Meet Future-Ready Tech

True innovation blends expertise with modern tools. Our equipment is developed by engineers who understand the nuances of the packaging world.

This blend of experience and emerging technologies like AI-powered software and smart packaging technology allows us to solve real-world challenges, from sustainable packaging to fast-changing market trends.

Sustainable Design For A Greener Tomorrow

Sustainable packaging doesn’t just mean using biodegradable materials. It also means optimizing material usage and reducing packaging waste across the board.

Our Vertical Packaging Machines are engineered to minimize film trim and reduce excess consumption. Small design choices like this make a big difference in carbon emissions over time.

Our machines support recyclable materials and packaging automation designed for environmental responsibility. They're also built to integrate seamlessly with future-ready materials like compostables and water-soluble films.

Each vertical packaging machine is built to align with waste reduction goals without sacrificing output. We believe sustainability should support, not hinder, production growth.

Smart Packaging Is Changing How Brands Connect

Smart packaging technology, such as Augmented Reality and embedded QR codes, is elevating consumer engagement. These innovations also support data analysis and customer feedback collection.

AR-driven packaging experiences let consumers interact with products digitally, adding value beyond the shelf. This adds a new layer of storytelling and transparency.

This interaction opens doors to better product development and smarter inventory strategies. Packaging becomes a feedback channel, not just a container.

With feedback loops built directly into the packaging, brands stay closer to the consumer than ever before. Over time, this fosters loyalty, drives repeat purchases, and supports quality improvement.

Real-Time Data Drives Continuous Improvement

In the packaging world, every second counts. By integrating predictive analytics and machine learning, our automated systems learn from historical data to improve efficiency over time.

Systems can identify patterns like common bottlenecks or causes of rejected packages, then automatically adjust parameters. This reduces costly trial-and-error in line setups.

These tools also help manufacturers monitor performance, prevent material shortages, and improve inspection outcomes. When combined with computer vision and inspection systems, they ensure consistent, compliant packaging.

Real-time dashboards provide actionable insights that reduce guesswork and support faster decision-making. Teams become more agile, responding to challenges as they happen, not after the fact.

Adapting To Every Industry Need

No two industries are alike, and our solutions reflect that. Whether it's food packaging, personal care, or pharmaceuticals, each vertical demands precise, adaptable systems.

We provide packaging types and configurations that cater to everything from delicate powders to heavy snacks. Our machines are designed to accommodate these variations with minimal manual adjustments.

From vertical packaging machines to advanced conveyor systems, our equipment is designed to handle a wide range of packaging materials and configurations. Operators can rely on smooth, automated transitions between product lines.

This flexibility keeps operations resilient, even when market trends shift. It also supports faster time-to-market, essential in today’s competitive packaging world.

Digital Twins, Simulation, And Testing—Before Production Even Begins

Thanks to digital twins and simulation tools, packaging lines can now be tested virtually before a single product hits the belt. This ensures every detail—speed, film type, weigher behavior—is optimized before going live.

Simulation helps identify issues before they disrupt real-world output. Line layouts, product flows, and even inspection points can be fine-tuned digitally.

By simulating real-world conditions, we eliminate unnecessary rework and support smoother startups. Our engineers can even use simulation to train operators on a digital replica before the machine arrives.

This not only boosts packaging speed but also ensures the highest level of quality control right from the start. With fewer delays and less waste, your packaging process becomes smarter from day one.

Packaging Automation That Evolves With You

Innovation doesn’t stop once the machine is delivered. Our packaging automation systems are built to scale as your business grows.

With modular designs and software-driven adaptability, your equipment stays aligned with your long-term goals. That’s the value of automation engineered with tomorrow in mind.

Let’s Build The Future Of Food Packaging Together

At Wolf Packing, we bring decades of experience and forward-thinking automation to every solution. Whether you're exploring smart packaging, AI in packaging machines, or full-scale packaging automation, we’ve got the tools and expertise to help.

Call us today at (657) 776-1813 to explore how our automated packaging systems can transform your operations. Let’s redefine what your packaging line can do.