Key Takeaways

- Vertical form fill seal machines (VFFS) are essential for packaging automation and optimizing your packaging process.

- VFFS machines provide measurable ROI by improving filling accuracy, increasing cycling speed, and reducing labor costs.

- Understanding key performance metrics like sealing technology, bag styles, and continuous motion can help you assess the effectiveness of your packaging solution.

- Investing in servo-driven VFFS machines and volumetric cup fillers can significantly enhance production capacity and accurate weight control.

- Food packaging and non-food applications can both benefit from the advanced features of vertical packaging equipment.

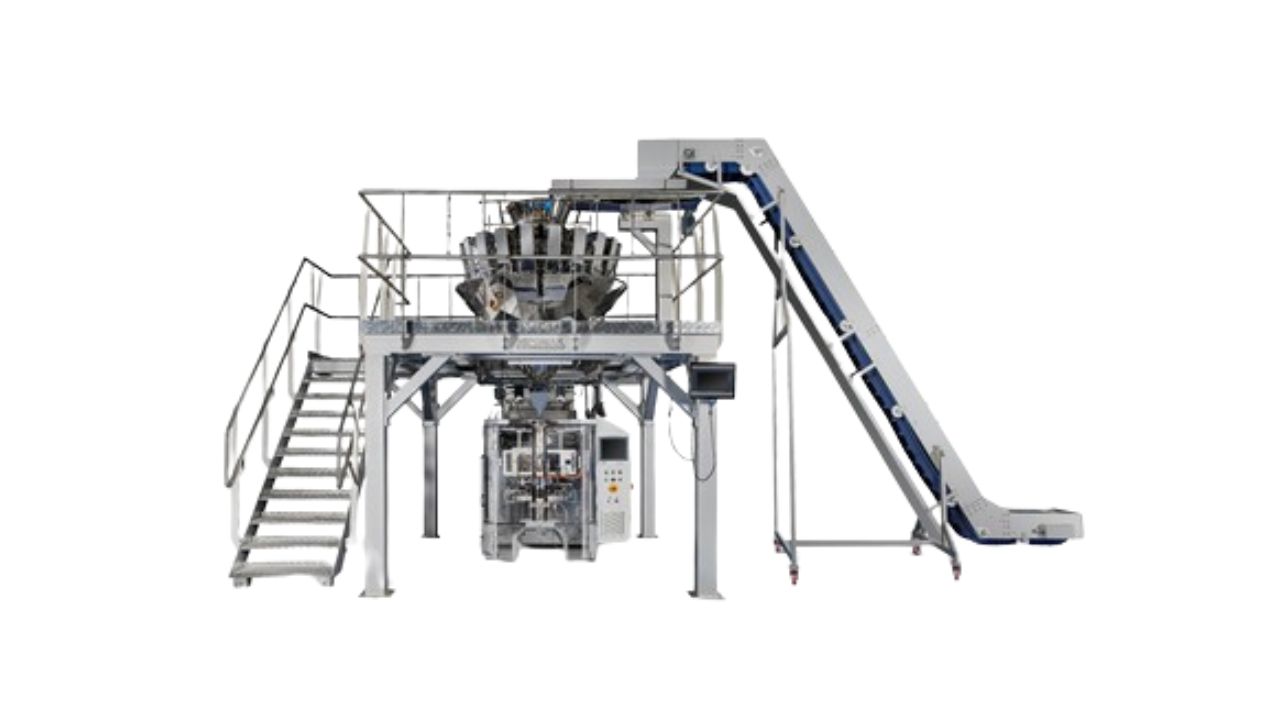

Vertical form fill seal machines (VFFS) are widely used in packaging automation because of their efficiency, versatility, and reliability. These machines streamline the packaging process, offering a seamless solution for a variety of product types, from food packaging to non-food applications.

Whether you’re filling pillow pouch packaging or other bag styles, VFFS machines offer high-speed capabilities and accurate weight control, delivering measurable ROI over time. In this blog, we’ll examine real-world performance metrics that contribute to the ROI of vertical form fill and seal systems, highlighting how they improve your packaging processes and provide long-term value.

Key Metrics to Measure ROI of Vertical Form Fill Seal Machines

To understand the ROI of a vertical form fill seal machine, it’s important to focus on key performance metrics that directly influence your packaging efficiency and bottom line. Below are the critical factors to consider:

1. Filling System and Accuracy

- VFFS machines are designed for filling systems that ensure precise and efficient product dispensing. This is essential in applications where accurate weight control is crucial, such as in the food packaging industry.

- Volumetric cup fillers and combination weighers are commonly integrated with vertical form fill and seal machines to ensure consistency in the filling process, leading to reduced product loss and higher profit margins.

2. Bag Style and Bag Length Customization

- The ability to customize bag styles and bag length allows for a flexible packaging solution. Whether you need pillow pouch packaging, stand-up pouches, or other formats, a vertical form fill and seal machine can meet your specific requirements.

- Efficient bag assembly and the ability to change bag styles quickly contribute to faster turnaround times, improving the cycling speed and boosting overall production capacity.

3. Control System Integration

- The control system is a pivotal part of vertical packaging equipment. It allows for easy monitoring and adjustment of packaging parameters such as seal length, forming tube adjustments, and product sensing.

- Automatic VFFS packing machines equipped with modern control systems ensure minimal human intervention, leading to better consistency and reducing errors that can negatively impact production.

4. Sealing Technology

- Sealing technology plays a critical role in determining the effectiveness and reliability of your packaging. Vertical sealing systems are designed to provide airtight seals, ensuring that the product stays fresh and undamaged during transport and storage.

- Servo-driven VFFS machines typically offer higher precision in sealing, providing a superior vertical form fill and seal process compared to older pneumatic VFFS machines.

5. Cycling Speed and High-Speed Applications

- Cycling speed is a direct indicator of how fast your VFFS machine can produce sealed bags. Machines that offer continuous motion are particularly beneficial for high-speed applications, ensuring that production lines run efficiently and meet demand without compromising quality.

- By maximizing cycling speed and optimizing vertical packaging capabilities, VFFS machines can help businesses handle large volumes of products, improving overall output and profitability.

How Vertical Form Fill Seal Machines Improve Business Productivity

The ROI of a platinum vertical form fill seal machine isn’t just about the initial cost savings; it’s about long-term improvements in efficiency, productivity, and quality control. Below are some examples of how these systems enhance business performance:

1. Improved Packaging Speed and Efficiency

- VFFS machines can pack products quickly and consistently, significantly reducing the time it takes to fill and seal products. The ability to adjust for bag width and bag length ensures that these systems can handle a variety of product types with minimal downtime between different production runs.

- For industries with high-volume packaging needs, high-speed applications can lead to increased production rates, helping businesses meet growing demands and expand their market reach.

2. Enhanced Product Quality and Consistency

- With volumetric cup fillers, weighing systems, and automatic filling capabilities, VFFS machines ensure that each package contains the correct amount of product, contributing to consistent quality across all units. This is particularly important in the food packaging industry, where accurate measurements are vital for meeting consumer expectations and regulatory standards.

3. Reduced Labor Costs

- Vertical form fill and seal machines automate much of the packaging process, reducing the need for manual labor. As a result, labor costs decrease, and production lines become more streamlined. Automated machines with servo-driven systems also require less maintenance, which further contributes to cost savings.

4. Customization for Non-Food Applications

- Although VFFS machines are most commonly used in the food industry, they are also highly adaptable for non-food applications. Industries such as pharmaceuticals, chemicals, and even agricultural products benefit from the flexibility and precision that VFFS systems provide, improving efficiency across various sectors.

5. Reduced Waste and Material Savings

- The precision of servo-driven VFFS machines ensures that each bag is filled to the exact weight specifications, reducing product waste and minimizing material usage. Whether it’s pouch bag packaging or pillow pouch packaging, businesses benefit from the ability to reduce packaging costs over time while still maintaining high-quality standards.

Maximize ROI with Vertical Form Fill Seal Machines

Investing in a vertical form fill seal machine offers a significant ROI by improving packaging processes, enhancing filling accuracy, and reducing labor and material costs.

By understanding the key performance metrics such as sealing technology, cycling speed, and control systems, businesses can ensure that their VFFS machines continue to deliver value over the long term.

Contact us today to explore how a vertical form fill seal machine can transform your packaging operations. Our expert team can help you choose the right VFFS machine to maximize your business productivity and ROI.

Frequently Asked Questions

What factors affect the ROI of a vertical form fill seal machine?

Key factors that affect ROI include cycling speed, filling accuracy, sealing technology, and control system integration. Efficient packaging automation reduces labor costs, increases output, and minimizes product waste, leading to higher returns.

How can I improve my vertical packaging system’s filling accuracy?

To improve filling accuracy, use combination weighers and volumetric cup fillers to ensure precise product measurements. Integrating advanced control systems and load cells also helps maintain consistent fills across production runs.

What are the advantages of using servo-driven VFFS machines?

Servo-driven VFFS machines offer higher precision, faster speeds, and better sealing technology compared to pneumatic VFFS machines. They provide more control over the bag assembly, resulting in higher productivity and packaging consistency.

What types of products can VFFS machines handle?

VFFS machines are versatile and can handle a variety of product types, including powders, liquids, granular products, and even irregularly shaped items. This makes them ideal for both food packaging and non-food applications like pharmaceuticals and chemicals.

How does a vertical form fill seal help in food packaging?

Vertical form fill seal machines are essential in food packaging because they provide precise filling accuracy, secure sealing technology, and efficient packaging processes. These systems help reduce waste and maintain high standards of hygiene and consistency.